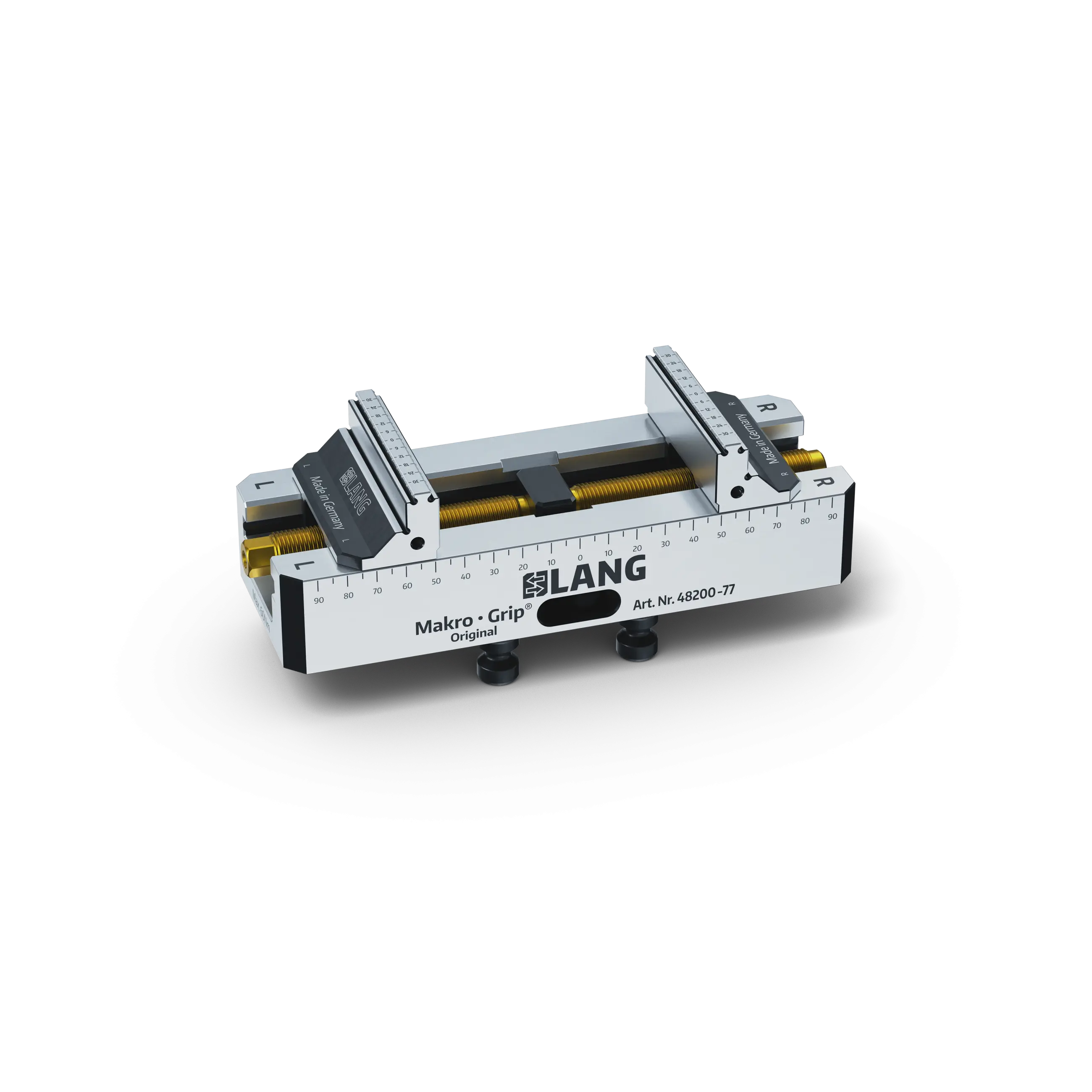

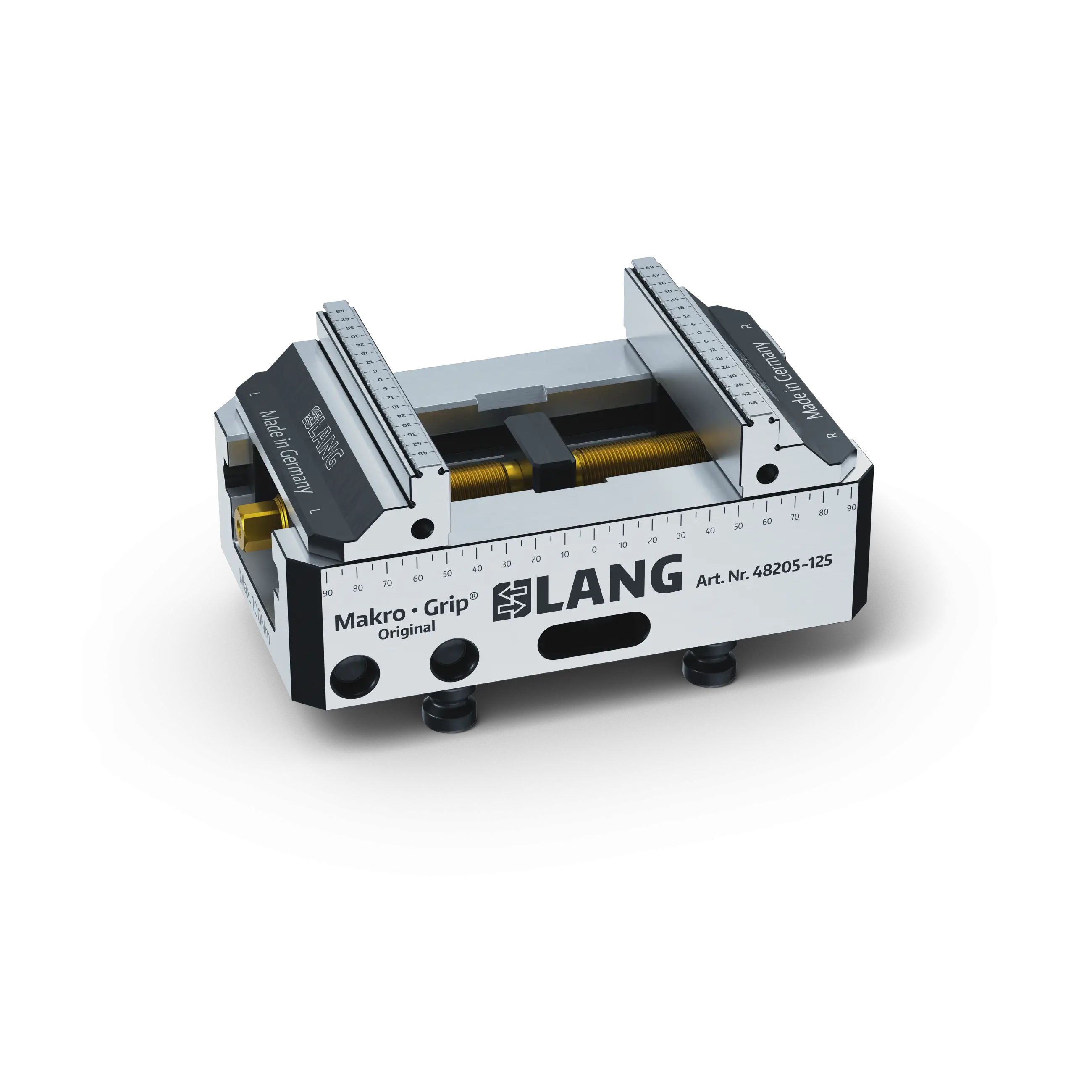

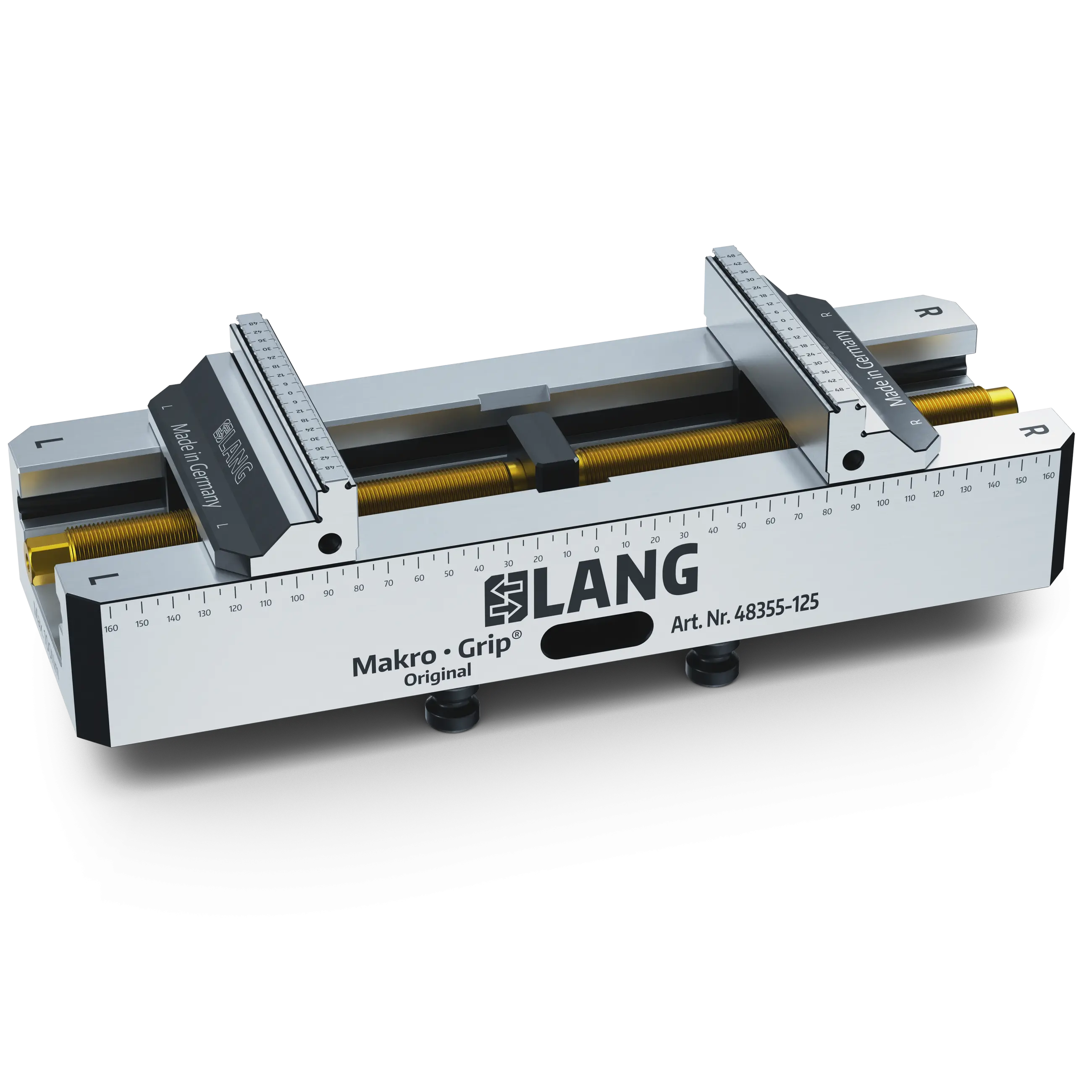

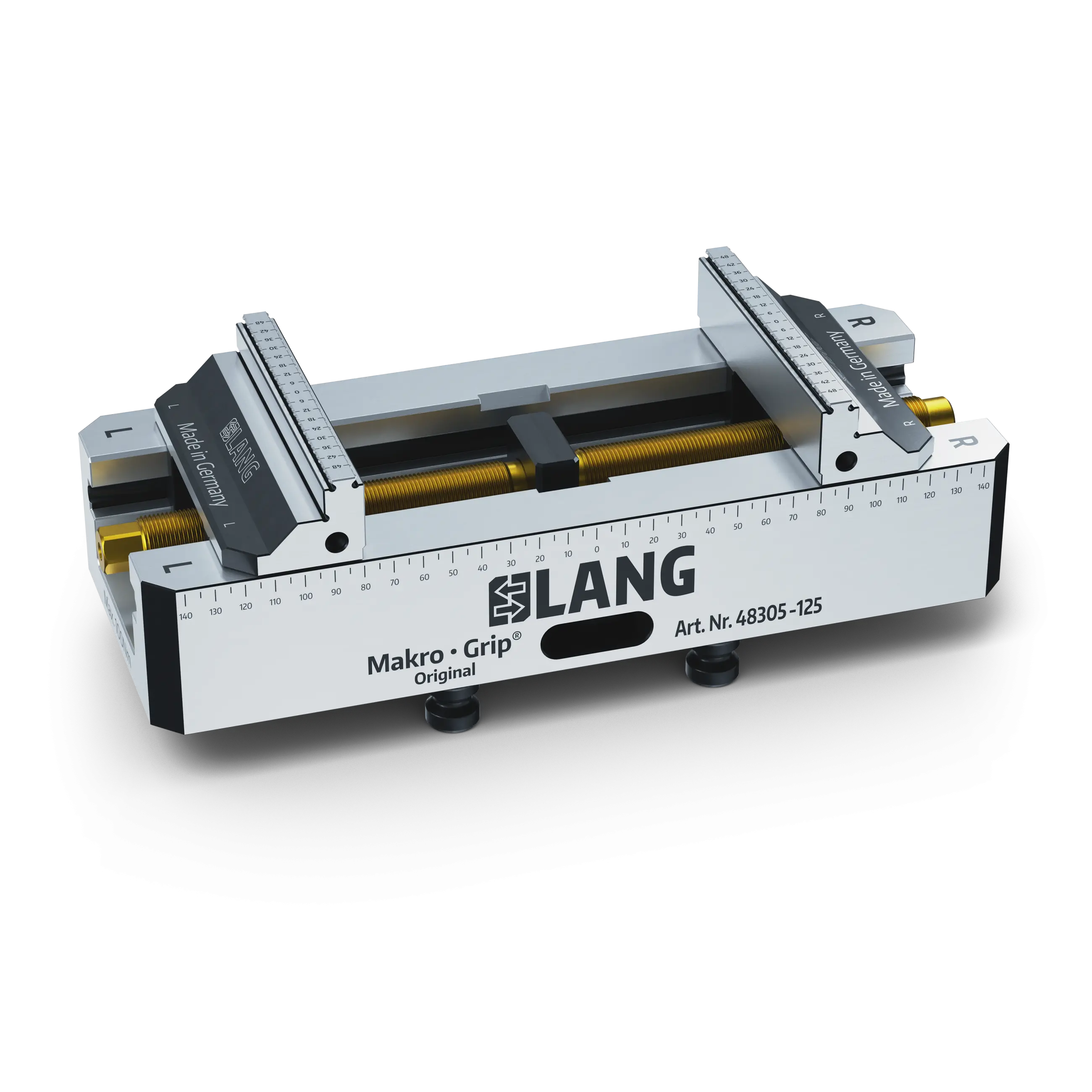

Makro•Grip® 125, 5-Axis Vise

Product Code - 48205-125

Catalogues

1. 2025 Lang Catalogue2. Lang Workholding

3. 2017 LANG Workholding

4. 2025 Lang Speciality Products

5. Lang MakroGrip Ultra

6. Automation

7. Zero-Point Clamping

8. LANG Aero & RoboTrex Compact.

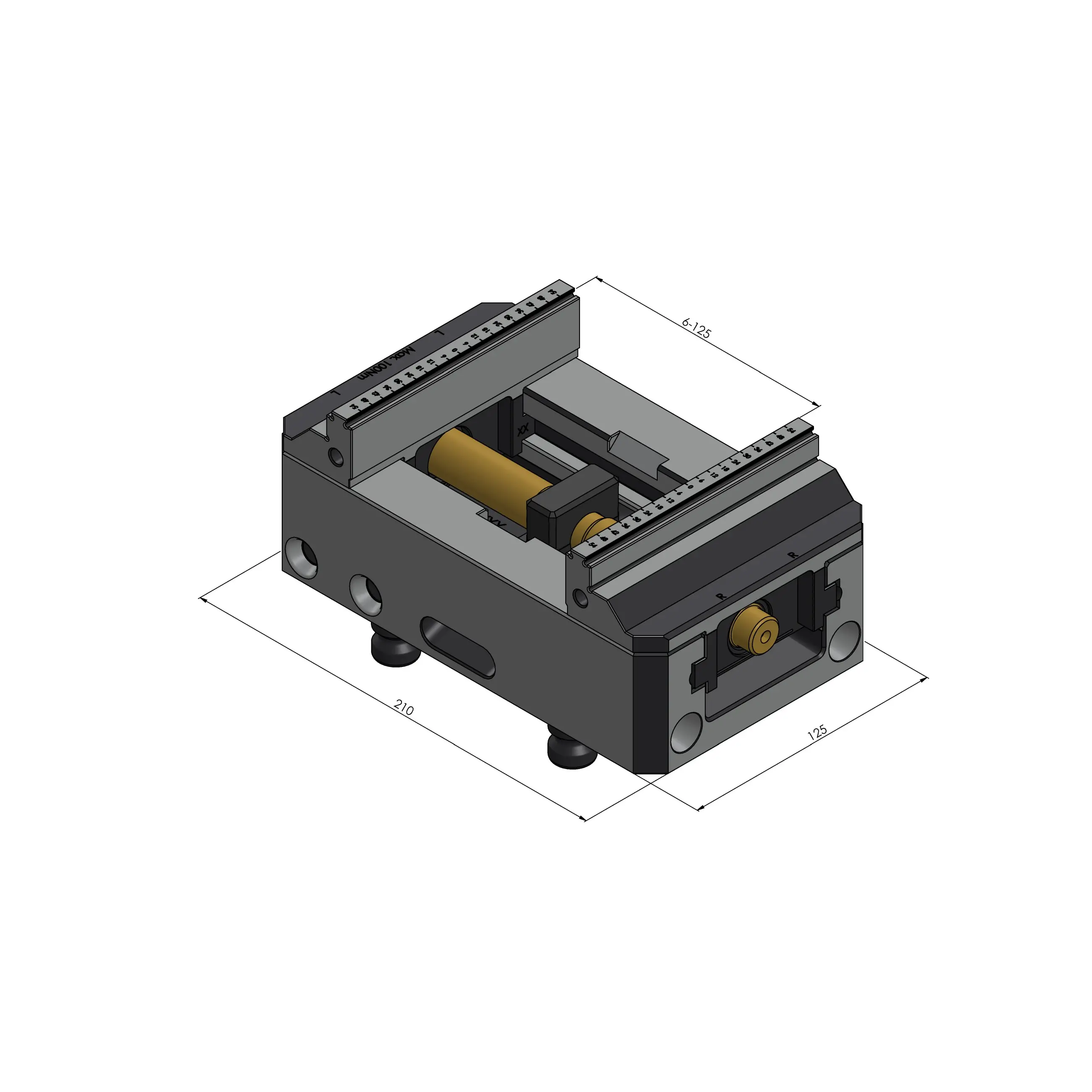

Key data at a glance

The Makro•Grip® 5-axis vise with a jaw width of 125 mm and a clamping range of up to 205 mm offers maximum process reliability in 5-axis machining. Due to its compact design and low interference contours, the workpiece is ideally accessible for the tools used. Thanks to its form-fit clamping, it achieves maximum holding forces despite low clamping pressure. Even with high-tensile material, it is able to clamp workpieces without distortion. The gentle clamping also means that there is no wear on the 5-axis vise. This vise version can be used both in manual CNC machining and automated with the RoboTrex 96 automation system.

Further Information

More Options:

Torque

100 Nm

Maximum allowed torque

Clamping stud size

20 mm (0.79")

Diameter of clamping studs

Clamping force

20.000 N

Clamping force at maximum torque

Centering accuracy

±0,02 mm

Centering tolerance of vises

Automatable

Yes

Automation interface included

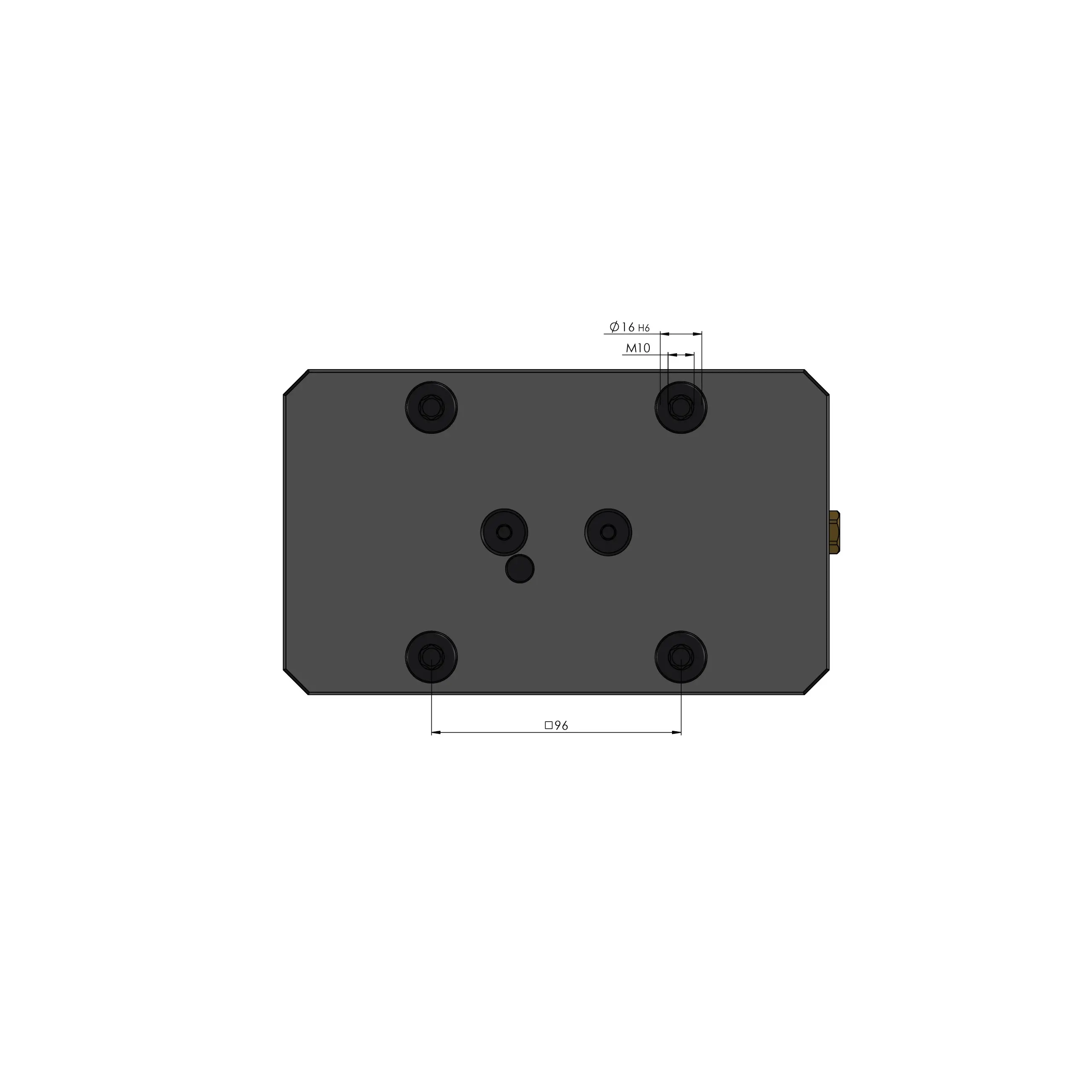

Grid system

96 mm (3.78")

Zero-point pitch

Notice:

Can be used in the RoboTrex automation system.

Scope of delivery:

Single components features:

Makro•Grip® Stamping Technology and Raw Part Clamping

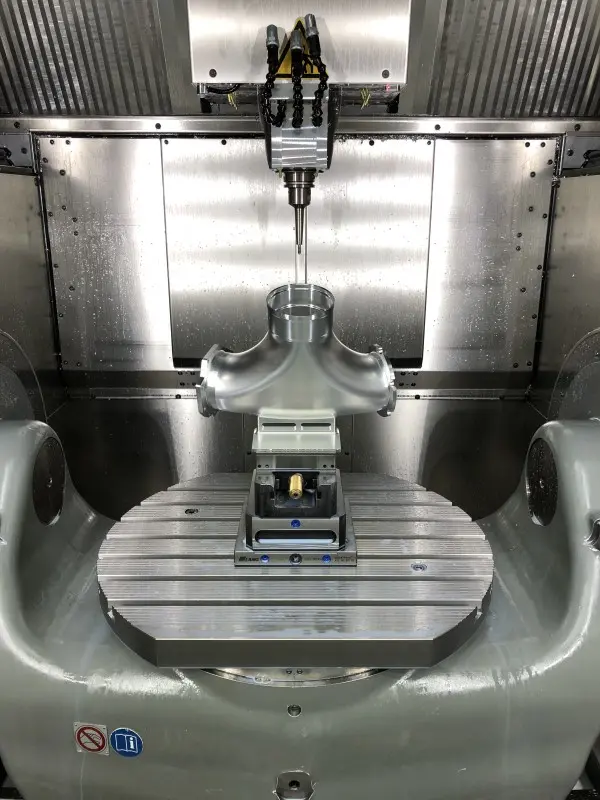

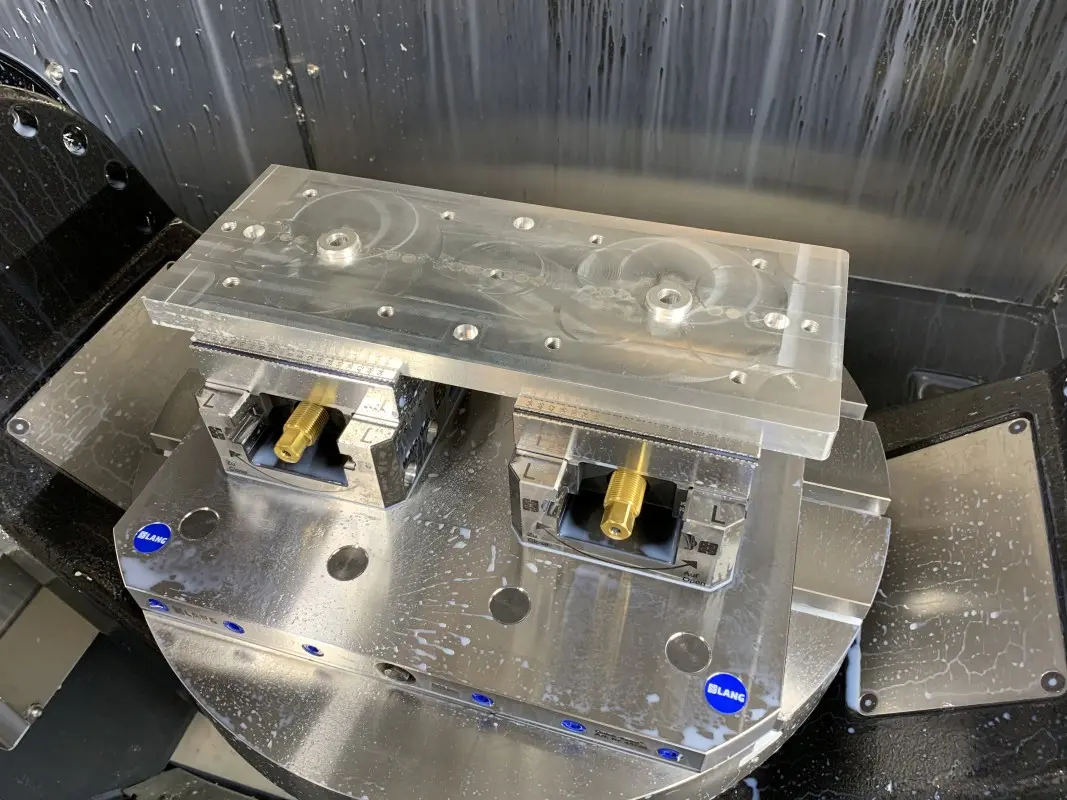

The Makro•Grip® 5-Axis Vise and its unique benefits of the stamping technology has been considered „The Original“ and a benchmark in the 5-face machining of raw parts for years. Its compact design and high holding forces make the Makro•Grip® 5-Axis Vise the ideal clamping device for machining raw parts.

Application pictures

en

en

English

English

French

French

Spanish

Spanish

Portuguese

Portuguese

(1).png)

.webp)